Negative pressure Leak Tester services|negative leak rate chart : chain store Leak testing is a broad term that includes a multitude of technologies. For the purposes of this article, different leak test methods will be referenced but not described in full detail. This article defines the broad term . 10 de abr. de 2023 · Se inscreva no canal e ative o sino de notificações para não perder nenhum lançamento!Siga nosso instagram principal: @lovefunkprodutoraSiga no instagram:@pi.

{plog:ftitle_list}

web23 de jul. de 2020 · Portal do Zacarias. IMAGENS FORTES! Adolescente é atropelado e escalpelado por caminhão-baú no bairro Nova Esperança, Zona Centro-Oeste de Manaus.

Vacuum Decay leak testing is used on a variety of products that can only be leak tested at negative pressure. The Optima vT can be used to leak test products, typically less than one liter at a fairly low vacuum, < 0.25 atm. Testing .Pressure testing services, including hydrostatic and pneumatic testing, verify the integrity and safety of your systems. With state-of-the-art equipment and experienced technicians, we .

pressure testing services near me

What is a Leak Test? Leak tests, on the other hand, are performed to detect and quantify leaks within a system. Rather than merely identifying weak points, leak tests aim to measure the leak rate or the amount of fluid that . Leak testing is a broad term that includes a multitude of technologies. For the purposes of this article, different leak test methods will be referenced but not described in full detail. This article defines the broad term .The instrument also can be used to test seal performance of specimens after falling and compression tests Product FeaturesNote1 Multiple Test Modes & Intelligent Statistics of Qualified Specimens Negative pressure method Multiple test modes including standard, multi-grade vacuum and methylthionine chloride mode Automatic test with traditional . Calibration Services; Leak Tester Selection; Leak Testing Training; Leak Tester Repairs and Service; . To specify a Leak Master the leak rate and test pressure must be quoted. In this case the leak master should be quoted as 0.5 cc/min @ 200 psig. . Sprint mD-V has a built-in venturi vacuum generator to produce negative pressure for vacuum .

The Pressure Decay test, also known as gauge decay, absolute pressure, leak drop or delta pressure leak test. This test method measures the drop in pressure on a gauge (transducer) during the leak test. Pressure decay leak testing is used to test products for leaks by trapping pressure inside a product and then measuring pressure loss.

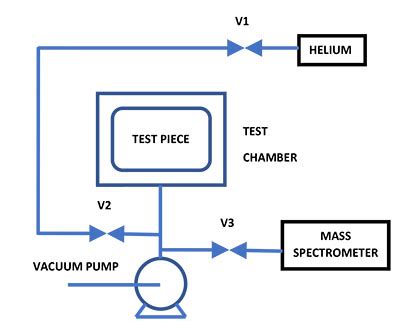

How each leak test method works impacts which methods are best for different applications. Selecting the right air leak testing method for your application includes identifying your required leak rate, maximum test pressure, maximum temperature differences likely to occur during test, and desired cycle time. Part design and environmental .Vacuum Negative Pressure Seal Tester, Find Details and Price about Compression Leak Tester Leak Detector Air from Vacuum Negative Pressure Seal Tester - Guangzhou Minder-Hightech co.,Ltd. . After-sales Service: 1 Year Warranty: Warranty: 1 Year: Measuring Range: Direct Pressure: Contact Supplier . First, let’s define a negative leak rate. The pressure loss of a production part is less than the pressure loss observed during the first calibration cycle (the control test) on the leak-free master part. This measures as a less-than-zero flow, or a negative leak rate.Guide to the Fundamentals of Helium Leak Testing What is helium leak testing? Helium leak testing is used to find small leaks or larger leaks in bigger volumes. The helium is used as a tracer gas and its concentration is measured. This guide to helium leak testing should outline the basics of using this leak testing method.

Cincinnati Test Systems is a leading manufacturer of leak detection, verification test units and leak test systems for all industries. Contact us today 513-367-6699NBC Leak Tester Mk II/Fitment tester is an automated field usage electronic tester which evaluates the fitment (leak tightness) of NBC respiratory full-face mask. This is a Controlled Negative Pressure (CNP) based quantitative fitment type instrument. Salient features: . sales and service network, reliability to maintain confidentiality. .

The low pressure system leak test in an anaesthetic machine is an essential component of a pre-test checkout. Although a variety of methods have been described to test for leaks within the low-pressure system, the negative pressure leak test using a suction bulb attached to the common gas outlet is commonly employed for its simplicity, wide applicability .In those cases where the leak rate can be determined during the course of the search for the leak without using a leak detector (see the pressure rise test below), this will often be converted to the helium standard leak rate. . This standard leak rate value is frequently needed when issuing acceptance certificates but can also be of service .Pressure decay is one of the most widely used methods of leak testing in manufacturing and is ideal for a sealed component with an access port. In this test, a product is attached to a leak tester and filled with air. Once pressurized, the air source is valved off and the pressure is allowed to settle.

For example, if you are performing a pressure decay leak test using 50 psi as your test pressure, accurate calibration ensures that your test instrument will consistently reproduce that test pressure, in a specific set of units of measure, in a standard set of conditions, every time you test, within a range of variation that is defined by .Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum (negative pressure). To perform a proper duct leakage test under negative pressure using an ORIFLOW duct leakage tester, perform .Leak Testing 101: A Primer 4 Vacuum Decay Leak Testing Similar to pressure decay leak testing, vacuum decay leak testing evacuates air from the part or system under test to detect leaks. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical .A negative pressure test, also known as the inflow test, is conducted to test the integrity of a well. While carrying out an inflow test, the underbalanced conditions in the well are created in a controlled manner for a differential pressure to act from formation to the wellbore.

Our full cleanroom services include a range of testing, including leak testing, for helium and positive pressure testing. Macfab’s focus on providing a low total cost of ownership through quality work is enabled through our leak testing of prototype and production parts. Leak testing is a form of Non-Destructive Testing (NDT). Pressure Decay Leak Testing: The Pressure Decay leak test is also known as gauge decay, absolute pressure, leak drop or delta pressure leak test. This test method measures the drop in pressure on a gauge (transducer) during the leak test. Pressure decay testing is used to test products for leaks by trapping pressure inside a product and then . Negative leak rate occurs when the pressure drop of the part being tested is less than that of the leak-free reference part. Negative flow occurs when the pressure of the test part increases or when it has smaller leaks than the reference, and this is called negative leak rate. Buy Yonligonju 28pack Universal Radiator Pressure Leak Tester Kit, Automotive coolant Pressure Tester kit for Motorcycle Car Truck (Red): . with better sealing, higher strength and good toughness, providing higher stability to prolong service life, and better vacuum effect it is good. . 4 customers mention "Performance" 4 positive 0 negative.

equipped with a L6-30 turn-lock plug required for 30-amp service. The fan can be . Step 4a — Typical Positive Pressure Testing Set-up using the Leak Detective 5-inch Test Components. 5 Step 5 — For positive pressure tests (5a), the fan discharge should be con-nected to the orifice tube. For negative pressure testing (5b), the fan intake will

The pressure decay leak tester uses a sensor to measure the pressure drop – it does not measure the leak rate. However, most customers want to see the result of the leak test displayed as a leak rate because the engineer who designed the part declared a leak rate as part of the specification. Understanding the negative pressure test on a drilling rig is crucial for maintaining control and ensuring safety. This article explains the importance of this test and provides a step-by-step procedure for conducting it effectively. . If the pressure drops, it may indicate a leak in the chamber or a malfunctioning component that needs .

Leak Testing 101: A Primer 4 Vacuum Decay Leak Testing Similar to pressure decay leak testing, vacuum decay leak testing evacuates air from the part or system under test to detect leaks. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical .Negative pressure leak test machine is a equipment that performs IPX8 waterproof inspection on the outer casing of the product through the principle of negative pressure detection. It is differ from t . [email protected]. : https://www.pegotester.com h ttps://www.pegotesters.com. TEL: 86-(0)795-3560528 FAX: 4008266163 ext. 29929 .

pressure decay leak test pdf

positive impact of animal testing

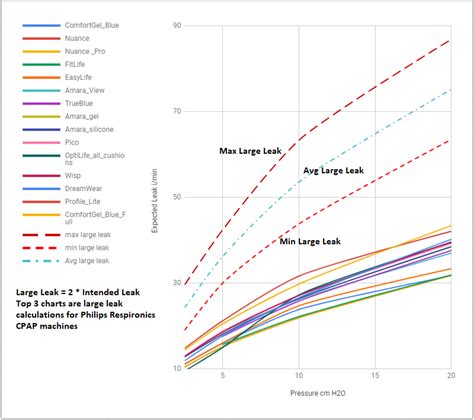

negative leak rate chart

webFamous American streamer IShowSpeed became a trending topic on Wednesday, as he accidentally exposed his genitals while live on YouTube. The moment quickly went viral, .

Negative pressure Leak Tester services|negative leak rate chart